Your safety is our business

Rider safety has always been number one priority. The Newlane Helmet has been certified to EN 1078 - The European Safety Standard.

We've been developing it for more than six years with a team of specialist designers and engineers in the UK and around the world. Together they’ve ensured every single component of the helmet is as robust as possible.

If you've chosen the Newlane with the Mips safety system, here's how it works:

Rotational motion is a common cause of concussions and more severe brain injury in oblique hits to the head. The Mips® safety system consists of a low friction layer mounted inside the helmet. In a crash, the low friction layer is designed to move slightly inside the helmet to help redirect forces away from the head. This is intended to help reduce the risk of brain injury.

We manufacture all our helmets in the UK to ensure they are built with precision and are of the highest quality.

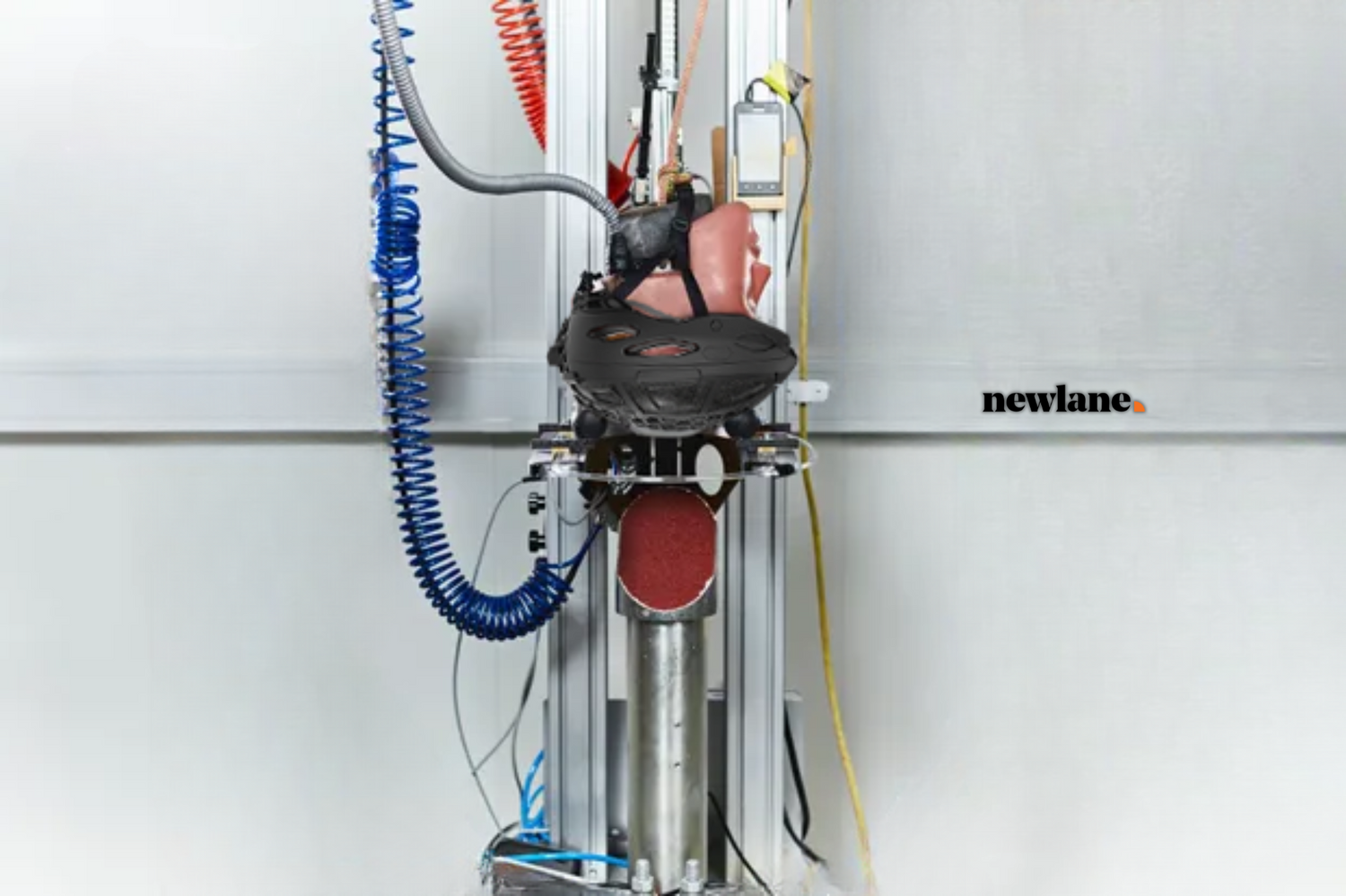

How the helmet is tested

To pass the EN 1078 standard, helmets are put through a series of tests that simulate cycling accidents. These high speed impacts are on the front, back, sides and crown of the helmet, using flat and kerbstone steel anvils.

When dropped onto an anvil, a helmet must ensure a force of below 250G reaches the head-form (G is the measure of gravitational force). The Newlane Helmet averages just 134G, demonstrating very clearly its effectiveness at absorbing the kind of force exerted in an accident.

All these tests are carried out after the helmets are heated up (+50 degrees), cooled down (-20 degrees) or aged under UV light. This ensures they offer protection in all kinds of conditions.